Features of the VH4-Servo Four-side sealed bag packaging machine

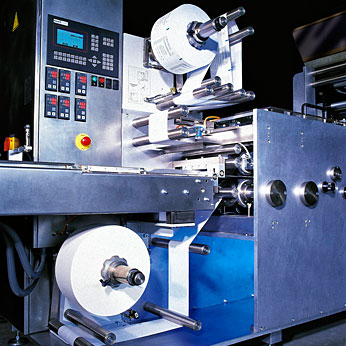

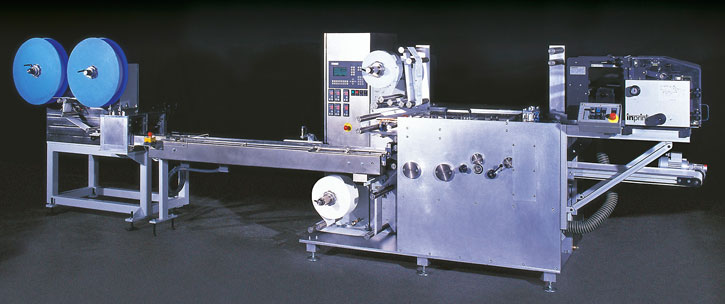

The machine primarily consists of the following units:

- feed finger chain

- basic machine frame

- film rack

- forming set

- longitudinal sealing unit

- transversal sealing unit

- carry-off line

The four-side sealed bag packaging machine uses two reels of packaging material.

An unwinding unit unwinds the reels of packing material. With the two-part, adjustable forming set, the two webs of packaging material are positioned on top of each other. Through the feed finger chain, the product is put on the bottom web of packaging material. The two webs are then closed at the side by the following longitudinal sealing unit. In the next production step, the transversal sealing unit closes and cuts the filled webs of packaging material. The finished four-side sealed bags are then transported further on the carry-off line.

Specifications:

Machine height: 1800 mm

Machine length: 4300 mm

Machine depth: 1050 mm

Packaging width: 20 - 300 mm

Packaging length: 30 mm - unlimited

Product height: 0 - 30 mm

Capacity: max 250 packages/min

(depending on product and wrapping material)

Power demand: 4 KVA

Air pressure 6 bar

Power supply: 220/380 V, 50/60 Hz

Protection class: IP 54

Weight: approx. 900 kg

Supplementary and special equipment:

Printing register control

Empty bag monitoring => "no product - no bag" function

Printing unit, e.g. embossed printing, ink jet, thermal transfer

Automatic feeding systems (customer-specific)

Film pre-unwinding

Euro-hole (DIN standard)

Double reel holder

Insertion device (picture or cardboard)

Perforation device for multiple packages

Packaging products:

The VH4-Servo Four-side sealed bag horizontal packaging machine is suitable for packaging CDs, seals, refreshing tissues, halogen bulbs, manuals, gloves, hygiene products, cannulas, catheters, compresses, moth papers, plasters, pipettes, writing implements, napkins, syringes, and many other products.

Industries:

Four-side sealed bag packaging machines are used in the chemicals industry, the hygiene industry, the food industry, the pharmaceutical industry, the dressing materials industry, or the confectionery industry.

Advantages at a glance:

Mechanics with electronically controlled servo motors. A safety ratchetting clutch limits the maximum torque of the transversal sealing unit. Thanks to the robust mechanic design, the packaging machine requires very little maintenance and is easy to service. Format sizes can be changed quickly. The machine is Made in Germany.